Welcome to RITCHIE Agricultural

OVER 150 YEARS OF MANUFACTURING EXCELLENCE

RITCHIE was established over 155 years ago as a blacksmithing service to the local community of Gateside in the County of Angus, Scotland. As farming advanced during the late 19th and early 20th Century, traditional blacksmithing skills were replaced with the manufacturing of a small range of innovative implements designed to improve efficiency and reduce labour inputs as horsepower gave way to steam and tractor power. This business expansion necessitated relocating from the country into the town of Forfar where RITCHIE continued to develop and manufacture products for both the livestock and arable industries.

Today RITCHIE occupy a 14-acre site on the outskirts of Forfar, which houses their manufacturing and business centre, and a manufacturing depot situated in the Midlands. Investment in the latest galvanising, CNC, robotic and computer technologies support a skilled and motivated workforce with products supplying the UK and world markets

Depots

Today Ritchie has state of the art, modern manufacturing facilities in:

- Forfar, Scotland

- West Midlands, England

- Weihai, China (joint venture with Weihai Gaosai)

Customers

Ritchie customers are as diverse as our products, including multi-national blue chip organisations as well as small independents.

Products are delivered worldwide including the North Sea, Europe, West Africa, Caspian Sea, North & South America, Brazil, Australia, New Zealand and the Far East.

Hot Dip Galvanising

RITCHIE galvanised products incorporate a highly protective zinc-iron alloy coating to protect and preserve all exposed surfaces from the corrosive effects of animal and silage effluent.

Components pass through acid cleaning baths and a pre-dip fluxing system prior to galvanising to extend the life of RITCHIE products.

Hot dip galvanising to standard BS EN ISO: 1461:2009.

Prices

Carriage paid to British mainland merchant premises. Any standard items returned will be subject to a handling charge of 15%. Errors and omissions excepted.

Shortages and/or damage must be reported in writing or emailed within 48 hours.

History

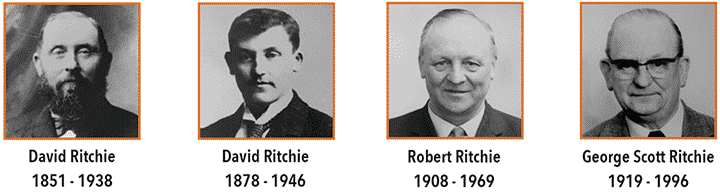

1870 - 2015

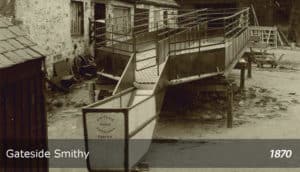

1870

David Ritchie, the great grandfather to two of the present Ritchie directors (David – Company Secretary and Robert – Agricultural Sales Director), took over Gateside Smithy, just outside Forfar when he was 29 years old.

1915

David’s two sons, James (originally a veterinarian) and David both became blacksmiths and decided to leave country blacksmithing and develop agricultural engineering at Whitehills in Forfar.

The repair of implements took up most of their time with an increasing demand on sheet metal products such as Potato Baggers and Fodder Wagons

1922

Staff had increased to four, with David’s eldest son Robert (whose looks defy his age) joining the firm at the age of 14.

Repair work still took priority over the manufacture of new implements, however additional new products were introduced such as Pig Feeders and Food Troughs.

1938

For the first time, non-family employees were invited into the business. World War II started and practically all efforts were put into implement repair.

1946

George Ritchie (David’s youngest son), who went to St. Andrews University to study medicine, joined the RAF upon the start of the Second World War and was then subsequently persuaded to join the family business.

1948

First product catalogue published. With the war now over, more emphasis was put on manufacturing new implements than repair. The product range at this time included tractor carts, end or side tipping, stack bosses, knife sharpening stands, oil tanks, lime spreaders, corn bins, water troughs and sheep dippers, many of these being novel products for the time. All of the non-local deliveries were made by the railways leaving from Forfar Station.

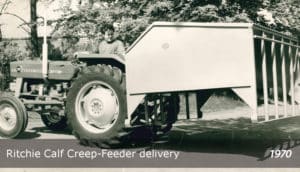

1950s

Ritchie had begun selling through the Ritchie dealer network throughout the UK. The product range increased to include a wide range of poultry, cattle, sheep and pig feeding and handling equipment. Robert (Bert) Ritchie was managing the business at this time.

1965

As a strategic move to address the so-called ‘Beeching Cuts’ of the railway networks and the closure of Forfar station, Ritchie’s first delivery truck was introduced and covered the whole of the UK! A door to door service was then available to the customers, which was so successful that a second vehicle was added by the spring of 1966.

1969

Land at Suttieside Farm purchased from Forfar Town Council. Originally developed as a storage site for finished products, the first factory was built by 1973 for fabrication work only.

At this time the product range continued to broaden with the introduction of bale handling equipment. This was a necessary development as having been predominantly in the livestock sector, a quieter summer season was experienced due to the seasonality of the livestock product range.

1973

Under the Conservative government, the UK entered the ‘Common Market’ by signing the ‘Treaty of Rome’. This sent the Agriculture industry into a volatile state and forced the company to look at alternative markets.

1977

The ‘Burke’ trophy was awarded to Ritchie at the Royal Show, Stoneleigh, for the ‘Transfer Weight Bale Transporter’. This machine revolutionised bale handling and was instrumental in the continued success of the business. Other Ritchie agricultural products have been recognised by various show societies with ‘awards of merit’ and silver medals being presented.

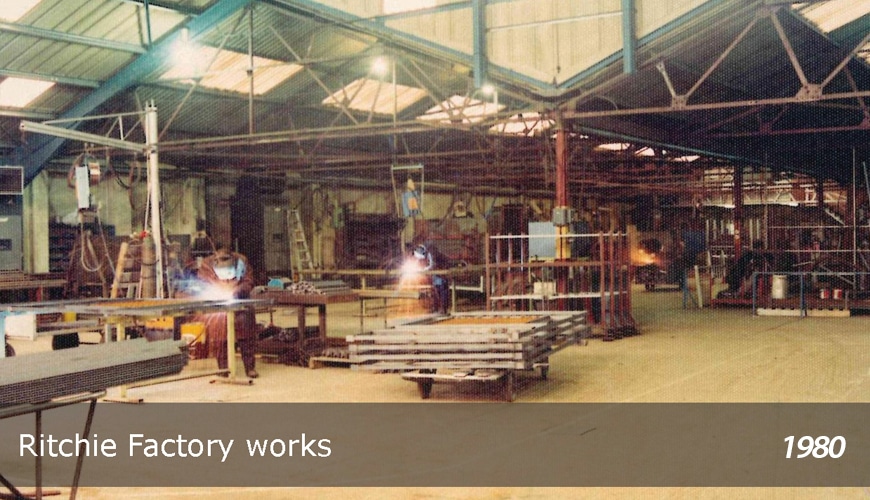

1980

By the early 1980s, the search for new markets had led into the blossoming Offshore Industry. This subsequently took Ritchie into the industrial gas supply industry, fabricating a range of gas cylinder handling equipment.

1990

By the early 1990s, Ritchie ingenuity had advanced enabled the company to become the leading supplier of gas handling equipment in the UK.

1995

Additional ground was purchased at Forfar both in 1990 and 1995 totalling approximately 7 acres to allow for further expansion.

1999

Forfar Galvanisers Ltd was established with a state of the art plant being constructed at the Suttieside site.

2009

As part of the company’s strategic growth plan, Ritchie Hua Engineering Ltd was established as a joint venture between Ritchie Limited and Weihai Gaosai Metal productions Co Ltd, to design and manufacture products in Asia.

2011

The company opened a facility in the West Midlands specifically designed to manufacture a higher volume of agricultural products close to one of the significant market centres and raw material suppliers.

2015

Today Ritchie employ over 140 people between the Forfar and West Midlands factories manufacturing and supplying equipment around the world.

Values

Quality

Quality in our design, fabrication and service are vital elements which make our business different. We are proud of our products and take pride in providing our customers with outstanding service.

Innovation

With a rich heritage in innovative design, we constantly look for new ways to resolve problems. Our products are designed not simply to meet specification but to provide optimum ergonomics, functionality and aesthetics. We invest heavily in improving our efficiency to allow us to provide better value and service to our clients.

Integrity

Integrity is behind everything we do. As a fifth generation family business, we take extraordinary care to treat our customers, people and suppliers in a respectful manner. This creates trust and allows us to build mutually beneficial relationships.

Performance

We strive for excellence in everything we do. We are passionate about achieving results which exceed our customer’s expectations. We are dedicated to obtaining any feedback which can help us improve.

Health, Safety, Equality and Quality

Health and Safety

The health and safety of our employees is of paramount importance. We exercise a strict health and safety policy to ensure our work activities internally and externally are completed with minimal risk. We actively encourage employees throughout the organisation, and even site visitors, to challenge any unsafe practice.

Environment

All staff at Ritchie are committed to minimising the environmental impact of our activities. This is achieved by minimising our energy usage, minimising material scrap, maximising recycling and minimising our CO2 emissions through fleet management.

Quality

Quality in our design, fabrication and service are vital elements which make our business different. We are proud of our products and take pride in providing our customers with outstanding service. Operating and accredited to ISO BS EN 9001:2008, we are also regularly audited by our customers and organisations such as DNV and Aprigaz.

Local Community

We strive to promote local business links within our own community, as well as the wider east coast of Scotland. One of our Directors, Tony Walker, is a founding member of the newly established Tayside Engineering Network which promotes sharing engineering best practice and business networking. We were also founders of the Angus Training Group (ATG) and have always had a Director on the ATG board.